Photocredit: Unsplash

Packaging — is a temporary vehicle to provide us the product that we want, safely and securely containing it at times. Other times, it is just an extra dressing that does not deliver value to the consumer, the supply chain that transfers it, and the environment. Packaging dematerialisation and reducing packaging waste could just be the key to unlock a dearth of new options.

How do we figure out alternative uses for packaging and how do we get rid of the unnecessary?

Most importantly, for businesses, how do we decouple, or isolate value brought about with packaging, so that we realise what alternatives to recouple it with, to deliver the same value.

Aligning with the principles of a circular economy, there are a few primary checks businesses can do before they go ahead with packaging dematerialisation.

Possibilities to explore

The possibilities explored would differ based on the openness to find solutions influencing a bigger system or a boundary, depending on whether;

- there is a decision to use packaging material

- there is a decision to question the fundamentals deeper to understand the experience, service, and value delivered with the product.

If a broader and bigger change is welcome, it is good to conduct a value engineering exercise for the respective products and services.

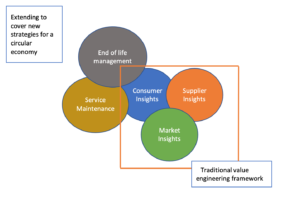

Value engineering is a systematic approach that fundamentally questions why each component of a product or a service is necessary and how much value it delivers to the final objective. It prompts to be critical about all components and to analyse against their alternatives. Most importantly, in identifying ‘value’, insights are gathered from customers, suppliers as well as competitors, helping to identify attributes of a product that customers may or may not value and what the value chain does to deliver it. This helps to a great extent to decide the priorities to focus on, in engaging in the exercise of packaging dematerialisation.

Consumer’s concern about maintaining service reliability with the product and issues with end of life management are two things to be added on in gathering consumer insights.

A deeper look into the consumer’s need for an experience/utility/service and exploring how to provide that without unnecessary materials is the objective of the exercise.

Here are some of the strategies that can be explored for both cases in general.

Solutions to achieve packaging dematerilisation or reduce packaging

Transforming packaging into a one-time investment providing long-term benefits and repetitive use is possible through the provision of refill options.

1.Refill options — Self-refilling

Heineken recently publicised an experiment they are conducting at a bottle shop in Paris which allows customers to bring their own bottle and refill with fresh beer from kegs available.

Having an extra channel for product delivery is definitely a plus for the business. There are other advantages such as simplifying the supply chain avoiding transporting, handling, and storing of packaged products. When containers subject to refilling enter the end of life, the consumers can return the bottles for recycling to the pub.

For consumers who prefer the convenience of having a beer opened at home, getting them to take the extra trouble of storing and bringing the containers back could only work if there is an incentive to refill every time. Creating that incentive through pricing or loyalty schemes is something to be seriously looked at.

2. Refilling options — Serviced refilling

In 2019, Unilever also promoted their plans to provide a reuse, refill option, looking at multiple alternatives.

There are services that can be offered to order refilling liquid online, refill at a filling station in a supermarket, or to order refilling services to pick up empty containers from home and delivering them back re-filled. The packaging material gets replaced by a refilling service in this instance.

While these options can be initially seen as disruptions to supply chains, the advantages are numerous. Building up a loyal customer base that form a community of long-term users, is one. Logistics resource optimisation with the use of options such as back-hauling of goods and reduced ‘product in transit load/value in transit’ on the supply chain is another. The trade-off could be the organising around delivering of small quantities, and the use of demand-based pricing if one way to overcome some of these challenges.

3. Packaging to provide a new and different value

Packaging can be designed in order to have an alternative use once its primary use is exhausted. For example, plastic crates can be used as seats, cardboard boxes can be used as storage containers, business cards can be used as reusable bookmarks, newspapers can be used as gift wrappers while gift wrappers can be used as calendars and wall hangers.

Not only the outer cover, sometimes the inner filling material such as wool or scrapped paper can be designed to bio-degrade as a fertiliser.

Conceptualising the new value of packaging material at the end of life at the design stage of the product, will help optimise the value of the secondary use.

Consumers demanding to know the value of a primary product as well as its associated secondary use is not a reality too far away. Having that answer in-hand would not only help businesses communicate value better but be in the forefront at showing responsibility for product stewardship.

Where and when should the exploration start?

The answer is obvious — As early as possible and as much as possible at the inception.

Value engineering would help to question and understand the fundamental human need associated with a product and eliminate material that do not add value to increase the user experience. If service options are required to replace some of these packaging, that can be a strategic alternative. An example is to provide delivery options that take back packaging or repair or return services.

Evaluating these strategic alternatives for feasibility would be the next step. Perhaps there is a transition pathway to get to the desired point, but what matters is that a set of services are designed keeping the consumer need at the core and the ability to be at the forefront of delivering it innovatively.

In a study by Nielsen, an alarming 73% of global consumers said that they would definitely or probably change their consumption habits to reduce the impact on the environment (ref). If the alternatives can be offered while keeping the value to the consumer guaranteed, and if they are strategized to make business sense, these are clear and easy wins to get aligned with a circular economy.